Use Case #7: 5G connected digital industry

For industry to remain a driver of social prosperity in the digital era, it must balance efficiency with workforce well-being and societal progress. However, the push productivity, rapid digital transitions, demographic shifts, and external disruptions can cause companies to overlook the workers’ evolving needs.

Industry 4.0 should be seen as an opportunity to re-centre humans in industrial processes. Rather than replacing workers, digital technologies should enhance their capabilities, providing tools that support and optimise their tasks. By connecting workers to surrounding systems, digital solutions reduce, the gap between humans and machines, easing physical strain and improving working conditions, especially in repetitive or demanding tasks.

There are two thematic areas that show the role of the interaction between man and digital technologies in the transformation process that is characterizing the industry:

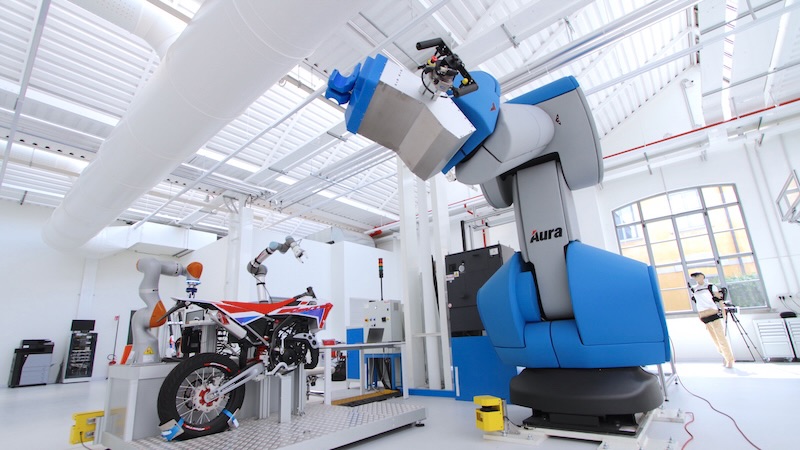

- Collaborative robotics.

- ”Smart” systems for operator assistance.

Collaborative robotics systems based on connected and repositionable devices have already been widely used in several 5G-based projects, including some involving the Politecnico di Milano and major manufacturers. The main goal of the use case is that of using advanced 5G connectivity to interconnected sensor systems that monitor the work area shared by robots and human operators with the collaborative robot integrated sensors and actuators and operate with a logic that take advanced of the enriched perception and actuation environment.

Smart operator assistance systems based on AR have already demonstrated an excellent level of technological maturity, already used for 5G-based projects. The main goal of the use case is to demonstrate how different tasks, like maintenance and configuration of the different industry 4.0 demo corners at MADE, can be accomplished with the assistance of AR systems that can guide the operator to execute tasks.